Most plastic bottles and aluminum cans in the U.S. can be recycled, but many aren’t. The reason? Contamination and poor sorting prevent billions of food-grade containers from being turned back into new products.

The Problem: Good Materials, Wasted

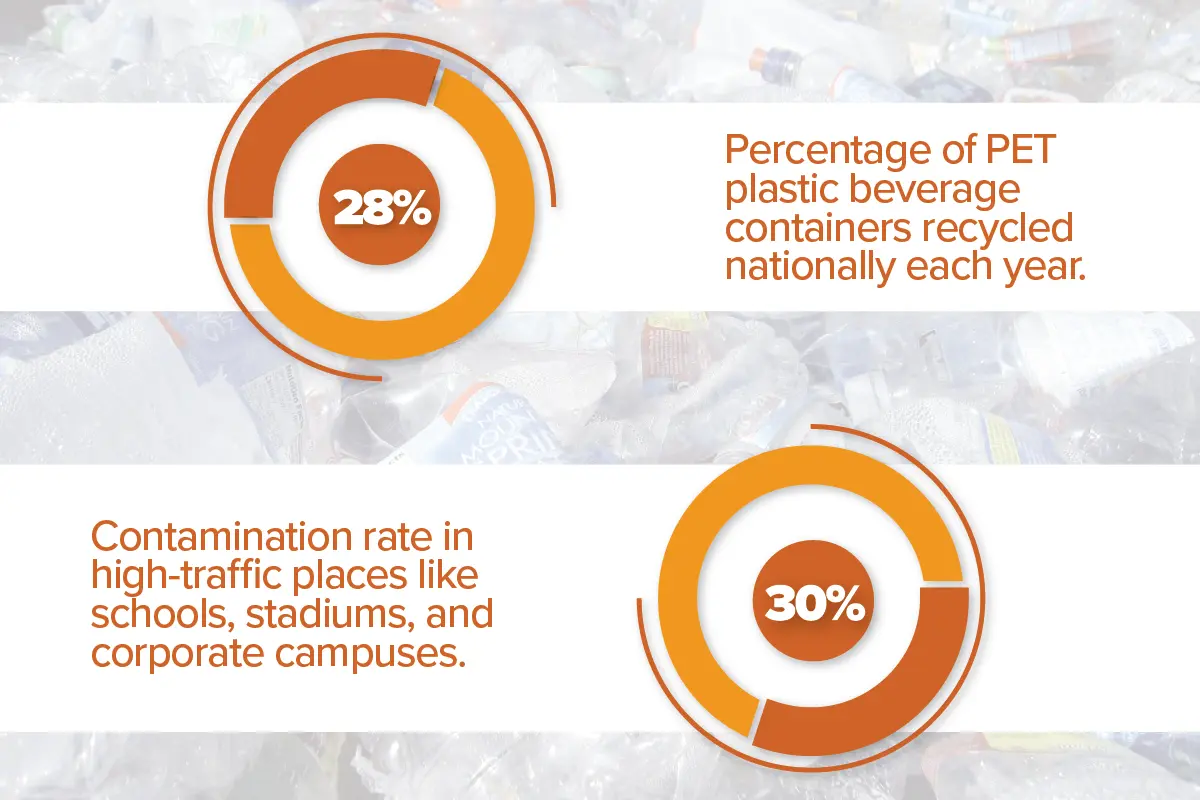

Nationally, only about 28% of PET #1 plastic bottles and around 45–50% of aluminum beverage cans are actually recycled. In high-traffic places like schools, stadiums, and corporate campuses, contamination rates can reach up to 30%. That means nearly a third of what people try to recycle ends up in the trash because it’s mixed with food waste, non-recyclables, or the wrong types of plastic.

Even when food-grade bottles and cans are collected, they’re often tossed into bins with trash or non-food packaging. This ruins the batch, making it impossible for recyclers to process the materials into new beverage containers. Processing plants also face restrictions; if they can’t prove the materials are food-safe, they’re not allowed to use them for products that touch food or drink.

Why It Matters

Resources that are used for beverage containers must meet strict food-grade safety standards. This applies to recycled polyethylene terephthalate (rPET) pellets and shredded aluminum processed for use in making new bottles or cans. That means it has to be clean, traceable, and separated from non-food-grade plastics. If bottles are mixed with garbage, recyclers can’t process them. Often, entire batches are thrown away, wasting valuable materials that could have been reused.

The Fix: Smarter Bins, Cleaner Recycling

Waste Wise Innovation offers a smarter approach to recycling by solving contamination at the source. The Topper Stopper™ smart recycling bin units are designed to retrofit on existing recycling bins and accept food-grade items using a patented lid system that only opens when it recognizes a verified recyclable item, such as PET #1 bottles or aluminum cans. Using barcode scanning and AI, Topper Stopper™ units block non-recyclables from entering the bin, greatly reducing contamination at the source.

The company also provides TS Analytics™, a real-time data platform that tracks contamination rates, collection volumes, and user behavior. With this insight, facility teams can spot issues early and make improvements. EcoLedger™ adds traceability (chain of custody), giving processors confidence that the materials they’re receiving meet food-grade standards.

Bottom Line

We don’t need more bins, we need better ones. Smarter collection and real-time tracking can finally keep clean, food-grade bottles and cans in the recycling loop, creating a sustainable supply chain. It’s a smarter way to recycle, and a better way to protect our planet.