Modern recycling stations are becoming increasingly sophisticated. You can find them in airports, stadiums, corporate campuses, and universities. These stations feature sleek touchscreens that identify items, provide real-time guidance, and even use animations to reward users. They are engaging and can successfully improve user participation.

However, there is a critical distinction that facility managers must understand. Most screen-based systems are designed to influence behavior rather than prevent mistakes. In the waste management industry, contamination is a mistake that organizations often cannot afford.

If a user drops food waste into the opening for recycled plastic or aluminum, the AI screen may have correctly identified the item. Despite this, the system still allowed the error to occur. This represents the fundamental gap between behavioral nudging and physical enforcement. It is the point where many high-tech solutions fail to deliver clean recycling streams.

The Rise of Smart Recycling and Its Core Dependency

Over the last several years, waste stations have integrated computer vision and detailed dashboards to track what people discard. This innovation provides valuable data, and in many settings, it helps improve awareness.

The challenge is that these systems share a common dependency. They only work when people comply with the instructions. In high-traffic environments, users are often rushed, distracted, or carrying multiple items. Public-space recycling cannot be designed for ideal users. It must be designed for real-world behavior.

Behavioral Nudging Versus Physical Enforcement

Screen-based AI is effective at educating, prompting, and measuring engagement. What it generally does not do is stop the wrong item from entering the wrong stream.

Physical enforcement is a different approach. It does not rely on a user’s attention span or motivation. Instead, it makes certain errors materially difficult or impossible at the point of disposal by controlling access to the bin.

This is the foundation of the Topper Stopper™ technology. It is an intelligent physical interface that uses item recognition to determine which opening should be available and restricts access accordingly. If the system recognizes a used beverage container, it opens the correct receptacle. If a user attempts to deposit incorrect items in the recycling stream, the opening remains restricted. This is not simply better signage. It is better architecture.

Why Contamination Impacts the Bottom Line

Recycling is a quality-sensitive commodity system. When contamination levels rise, material value drops and sorting costs increase. Downstream acceptance becomes harder, and collected loads become a higher risk for the facility.

Many engagement metrics fail to capture a vital reality. A program can show high participation rates and still lose money if contamination remains high enough to trigger extra labor or rejection fees.

Contamination is not an average. It is a quality constraint. Once certain thresholds are crossed, the economics of the program can flip from a revenue or neutral state to a significant cost. The most important question for a facility is not whether people engaged with a screen, but whether the stream was actually protected.

The Thirty-Year Bet on Education

The recycling industry has spent decades attempting to educate its way out of contamination. We have used labels, color-coded bins, and public awareness campaigns. Despite these efforts, national performance has plateaued.

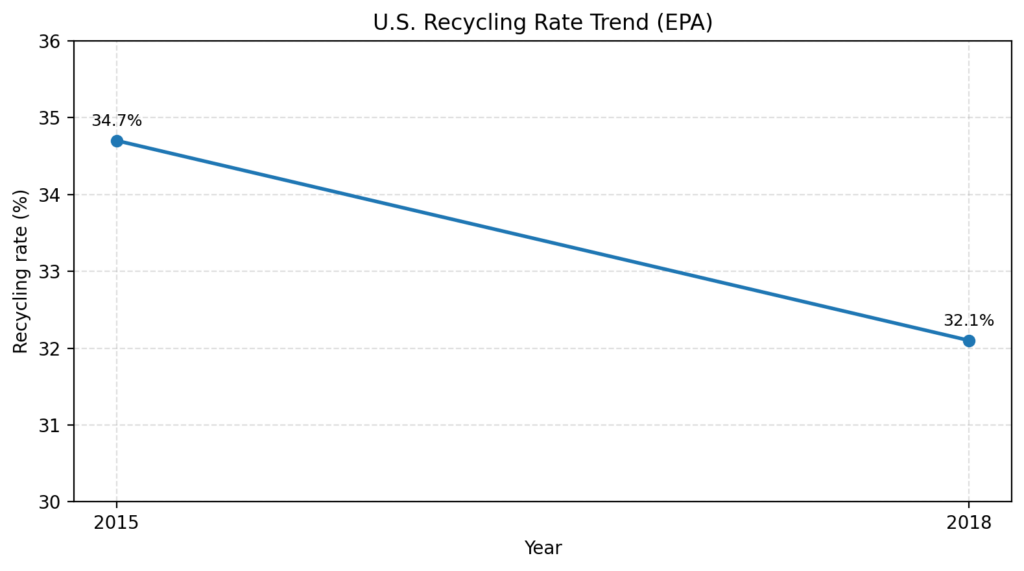

According to the United States Environmental Protection Agency (EPA), the national recycling and composting rate was 34.7 percent in 2015. By 2018, the most recent year for which this specific data set was published, the rate had declined to 32.1 percent. This trend suggests that behavior-based systems have hit a ceiling. You can review the national overview here: US EPA — National Overview: Facts and Figures on Materials, Wastes and Recycling.

Education is necessary, but it cannot carry the system alone. This is especially true in public environments where disposal decisions are made in seconds. If contamination remains structurally possible, it will persist regardless of how good the prompts are.

Why Engagement Metrics Do Not Equal Clean Recycling

A screen may increase correct decisions in many cases. However, the system must also account for the remaining edge cases. This includes the traveler rushing to a gate or the student distracted by a phone. If the system still allows the wrong item into the wrong opening, the contamination problem is merely reduced rather than solved. In many operational contexts, reduced contamination is still an expensive problem.

Topper Stopper™: Designing Out the Error

The Waste Wise Innovation approach starts with a different question. We do not ask how to convince people to do the right thing. We ask how to design the station so that doing the wrong thing is much harder.

Topper Stopper™ is built around physical prevention at the point of disposal. This makes the effectiveness of the system less dependent on user compliance. This shift is vital because public-space recycling is a flow-of-traffic environment. The system must work even when people are not actively trying to be perfect recyclers.

Prevention, Participation, and Proof

The Waste Wise Innovation platform is designed as a comprehensive stack.

- Prevention through Physical Control. This reduces common cross-stream errors by controlling which openings are accessible based on item recognition.

- Participation through Incentives. We add behavioral reinforcement through rewards and engagement because participation still matters for a healthy program.

- Proof through Auditability. The system creates a tamper-evident record of events, such as scans and collections. This supports stronger reporting and accountability for stakeholders who need more than just estimates.

While no digital ledger can validate a misidentified item on its own, it does provide an auditable record. This allows stakeholders to trust the recorded data, trace processes, and reconcile claims with actual collection activity.

The Real Cost of Good Enough

If a system reduces contamination but still allows it to occur, the organization continues to pay the price. This manifests as lower-value materials, extra labor, and operational friction.

The real question for any sustainability director or facility manager is how much contamination they are willing to tolerate. If the goal is to influence behavior, screen-first systems are an option. If the goal is to protect material quality at the source and build reporting on defensible data, you need infrastructure that goes beyond recommendations.

From Suggestions to Systems

AI screens are impressive technology, but they often treat contamination as an education problem. In the real world, contamination is frequently a design problem.

The future of clean recycling is not just smarter prompts. It is smart physical interfaces that reduce error by design. This is especially important where traffic is high and attention is low. Recycling is only valuable if it is clean, and it is only credible if the reporting is verifiable.

Ready to Stop Contamination at the Source?

Learn how Waste Wise Innovation’s Topper Stopper™ is redefining recycling infrastructure for airports, stadiums, corporate campuses, and municipalities.

Topper Stopper™: Prevention. Participation. Proof.

Waste Wise Innovation: Building the verified recycling infrastructure the circular economy demands.